Full Service Manufacturing

ENGINEERING

Comprehensive Engineering Support

Our skilled engineers collaborate with you to create a product design, ensuring compliance with your design intent and best-in-class manufacturing practices. Whether designing a new part or refining an existing design, we can assist you through each step of the process.

- Product Design & Development – Assisting with part geometry, material selection, and manufacturability optimization.

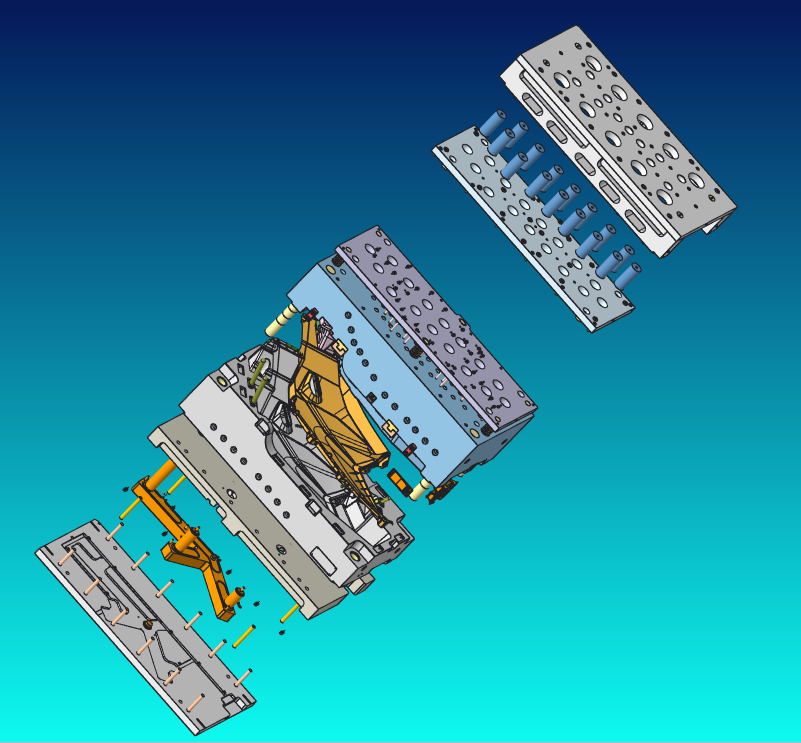

- Mold & Tooling Design – High-precision-engineered molds to deliver high-quality, repeatable production.

- Prototyping & Testing – Verification of design intent through prototype production prior to full scale manufacturing.

- Process Optimization – Streamline efficiency on vacuum forming and injection molding projects.

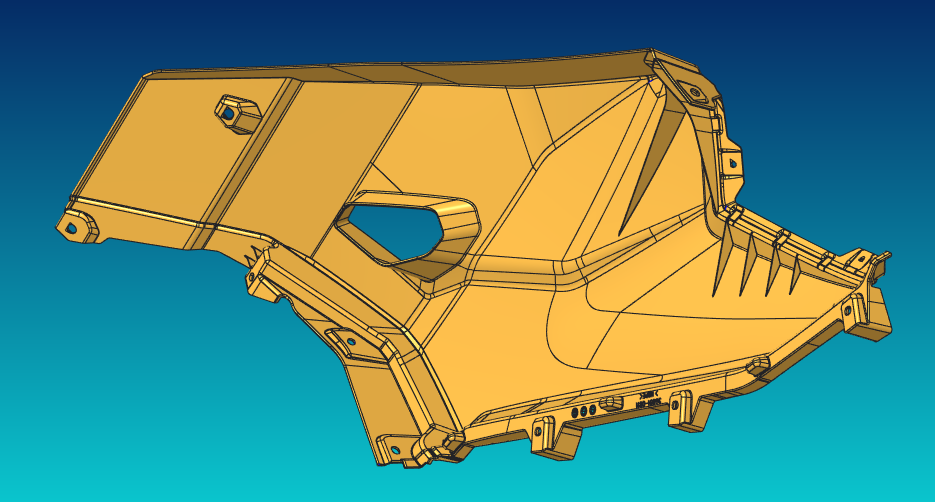

Computer-Aided Design & Manufacturing (CAD/CAM) Technology

We harness the latest CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) technology to enable fast-tracked product development, which reduces cost and time.

Our advanced digital solutions enable us to:

- Deliver accurate 3D models and simulations

- Provide scientific mold flow analysis for injection molding projects

- Generate precise CNC machining of vacuum forming and mold making

By integrating the newest engineering solutions, we maximize the accuracy, quality, strength, and manufacturability of your plastic parts.

Why Choose Design Plastics, Inc. for Engineering?

Because at Design Plastics, Inc. we deliver top-performing engineering solutions that meet your requirements.

- End-to-End Engineering Support – From concept to production.

- State-of-the-Art Design Tools – For efficiency and precision.

- Experienced Team – Four decades of plastic manufacturing experience.

- Cost & Time Savings – Optimization of design saves on production expense.

Design Plastics, Inc. has earned the prestigious ISO 9001 certification through Verisys Registrars®, a trusted auditing and certification body. This certification demonstrates the company’s commitment to maintaining the highest standards in quality management and operational excellence. By adhering to the rigorous requirements set forth by the ISO 9001 standard, Design Plastics, Inc. ensures that its products and services consistently meet customer and regulatory expectations. This certification reflects the company's dedication to continuous improvement, customer satisfaction, and producing high-quality custom injection-molded and thermoformed plastic products for worldwide industry applications. This achievement underscores Design Plastics Inc.'s focus on quality, precision, and sustainability in all aspects of their manufacturing process.

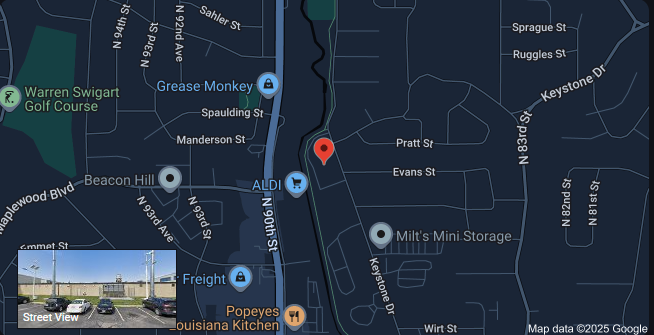

HQ & Omaha Plant

3550 Keystone Drive

Omaha, NE 68134

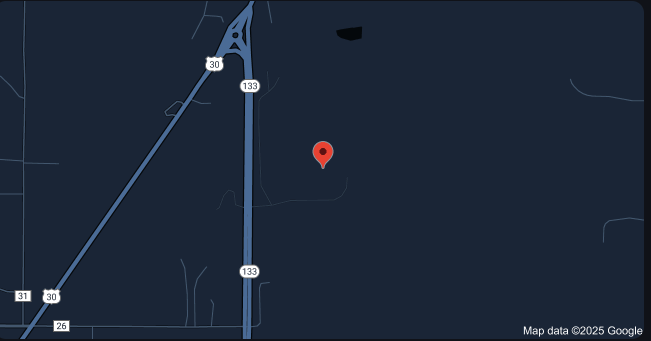

Blair Plant

9330 State Hwy 133

Blair, NE 68008