Full Service Manufacturing

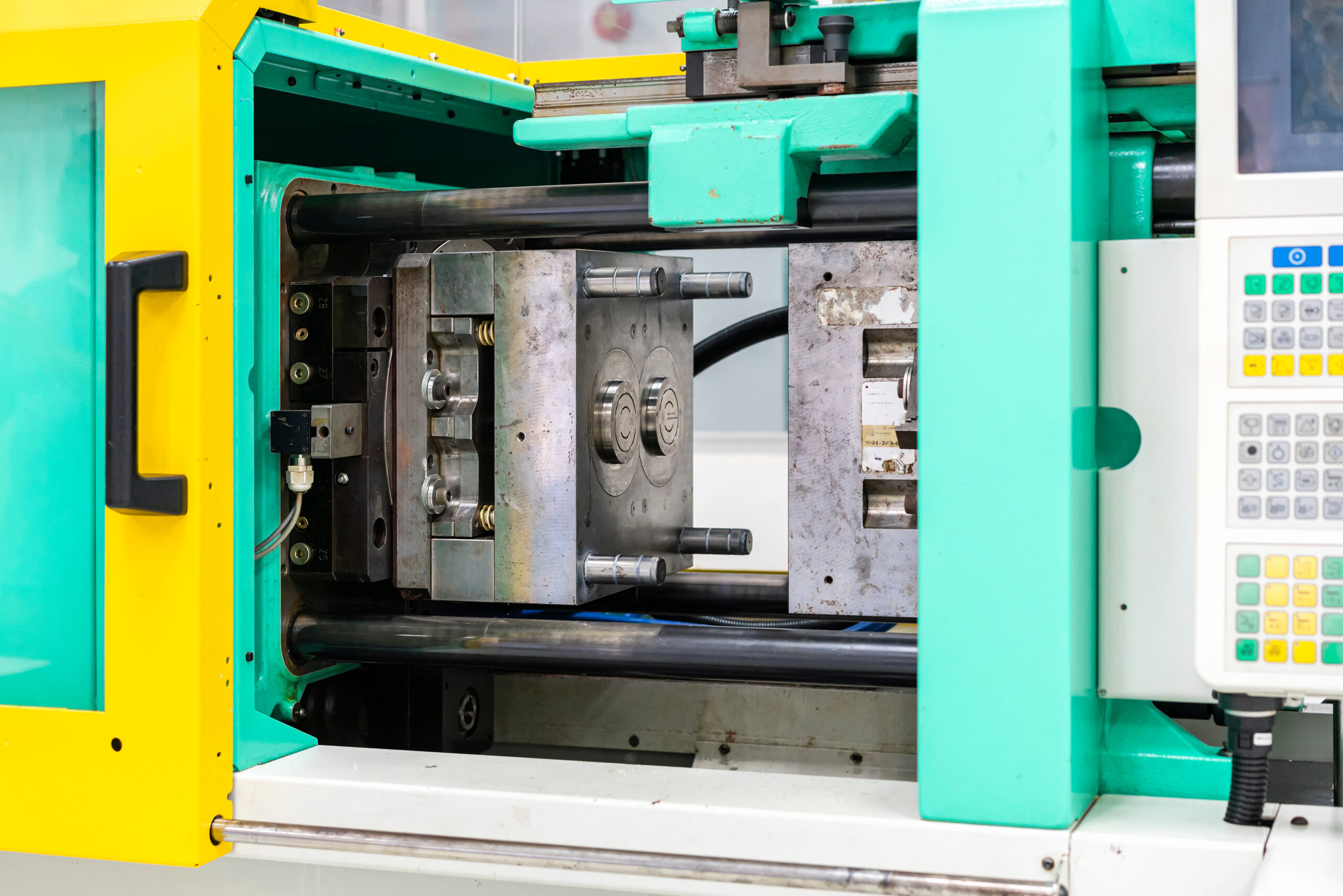

INJECTION MOLDING

Our Injection Molding Capabilities

At Design Plastics, Inc. we provide high-quality custom injection molding services to a wide range of industries. Whether from prototype through small or high-volume runs, we possess the capabilities and equipment to meet your needs.

- Press Sizes: Up to 730 tons, which allows us to produce a wide range of part sizes.

- Material Know-how: We shape a variety of thermoplastics, including ABS, polypropylene (PP), polyethylene (PE), polycarbonate (PC), nylon (PA), and more, to meet a variety of strength, flexibility, and durability requirements.

- Molding Solutions to Fit Your Requirements: Our team works with you from design to production, ensuring your design is cost-, performance-, and manufacturability-optimized.

- Precision Engineering: Sophisticated molding capabilities enable us to create tight tolerances, repeatable quality, and minimal waste.

Choosing the Right Process

Injection Molding vs. Thermoforming:

- When choosing a manufacturing process, it’s essential to consider cost, quality, volume, and part complexity.

- Injection Molding involves a higher upfront tooling investment but lower costs per part, ideal for high-volume runs.

- Thermoforming involves lower tooling cost but higher costs per part, often suitable for lower-volume runs or larger, less complex parts.

- Based on your project requirements, our experts will guide you in selecting the most cost effective and efficient production process.

Why Select Design Plastics Inc.?

At Design Plastics Inc., we are committed to delivering tailored injection molding services to assist in making your product concept a reality.

- Customer Satisfaction – Award-winning supplier for long-standing domestic & international Fortune 500 clients.

- Custom Mold Design & Fabrication – We partner with you to create the optimal mold & manufactured quality parts for your project.

- Scalable Production – Prototype to full production runs.

- Quality Assurance – High quality standards for precision and consistency in every part.

- Industry Experience – Decades of experience delivering state of the art plastic manufacturing solutions.

Design Plastics, Inc. has earned the prestigious ISO 9001 certification through Verisys Registrars®, a trusted auditing and certification body. This certification demonstrates the company’s commitment to maintaining the highest standards in quality management and operational excellence. By adhering to the rigorous requirements set forth by the ISO 9001 standard, Design Plastics, Inc. ensures that its products and services consistently meet customer and regulatory expectations. This certification reflects the company's dedication to continuous improvement, customer satisfaction, and producing high-quality custom injection-molded and thermoformed plastic products for worldwide industry applications. This achievement underscores Design Plastics Inc.'s focus on quality, precision, and sustainability in all aspects of their manufacturing process.

HQ & Omaha Plant

3550 Keystone Drive

Omaha, NE 68134

Blair Plant

9330 State Hwy 133

Blair, NE 68008